Metal Roof Systems for Mid-Atlantic Commercial Businesses

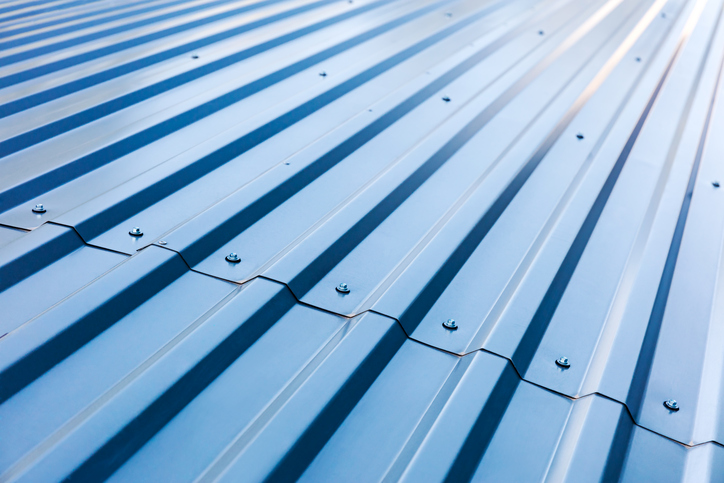

Lightweight but strong metal roof systems offer an attractive appearance combined with low maintenance costs for any slope.

Metal roofing can be used for most sloped roofs, from low-slope to a higher grade. Their stability and the variety of options available make them a popular roofing system for commercial buildings. Commercial metal roofs are excellent because of their variety. When installed as a low-slope roof, you’ll have a functional space to install other fixtures and appliances that are needed for your business’s daily functioning. As a higher-slope roof, you can give your building a different look.

David Maines & Associates, Inc. is ready to install your commercial metal roofing system. We are a customer-focused contractor who will work with you through the entire process, from planning through completion.

- Broad range of styles and colors

- Highly reflective cool colors lower cooling costs

- Panels of galvanized steel, aluminum, or copper

- Long-life coatings prevent the growth of moss, mildew, and fungus

- Life expectancy of 30+ years

Advantages & Disadvantages of a Metal Commercial Roof

Installing a new roof, especially when it’s for a commercial building, is a big job. The job will take time and cost a good amount. Before the job gets started, you want to make sure that you’ve chosen the right roofing option for your business. Looking at the pros and cons of a metal commercial roofing system will help you figure out if this type of roof is best for your commercial property.

Advantages of a Metal Roof

- Lightweight

- Long lifespan

- Durability

- Little maintenance

- Energy-efficient

- Variety

The first advantage of a metal roof is that it’s lightweight and easy to transport. When you’ve ordered your material, you may find some savings in the cost to transport them to your property. But just because this type of roofing material is lightweight doesn’t mean that it’s not made to last.

A metal roofing system can last as much as three times longer than a shingle roof. This is because it is durable and resistant to a number of different elements. Hail, snow, rain and even fire will have a limited effect on the roof. If a heavy storm or fire emergency occurred, you would not have to worry about your roof. Its resistance gives a metal roof excellent durability and longevity. A metal commercial roof can last 50 years or more.

Once the metal roof is installed, it will require little or even no maintenance. This saves your business a lot of money and hassle. When you take its lifespan into account, that turns into significant savings.

This roofing system is one of the most energy-efficient roofing options available. This quality can also save your business money over time. The metal roof will help keep warm air inside during the winter and cool air inside during the summer. When you’re operating out of a large space, like most commercial buildings, these savings could really add up. Throughout the lifespan of the metal roof, it could help you save a lot on energy alone.

Finally, metal roofs can be installed in a number of different colors, styles and textures. If you want to give your commercial building a certain look, a metal roofing system will give you the most options.

Disadvantages of Metal Roofing Material

- Higher up-front costs

- Can be loud

A metal commercial roof will save you money after it’s installed, but it will have a higher cost up-front. While it is a high cost up front, the savings could help the roof pay for itself over time.

If your building is in a colder climate, piled-up snow can easily slide off of the roof. This can turn into a hazard if it hits other fixtures in its path or even people on the ground.

Finally, metal roofs can be loud. They can make a lot of noise during installation and even after. Heavy rain and hail can be loud when they bounce off of a metal surface like the roof.

You need to weigh the advantages against the disadvantages of a metal roofing system. When you look at both the advantages and disadvantages of a metal roof, you’ll know if it’s the best fit for your building.

Commercial Metal Roofing Materials

There are several different types of metal that are used most commonly as roofing materials. Each type of material can give unique properties to your roof and will drive the cost. These are the materials that are used the most often for commercial metal roofing systems:

- Steel: This metal is strong and durable. Along with aluminum, it’s one of the most common materials for metal roofs. The steel is given a protective coating to prevent corrosion and rusting.

- Aluminum: This type is more lightweight compared to steel. However, this also allows it to dent more easily. Aluminum is only used for some residential roofing because it isn’t well-suited to commercial uses.

- Copper: Copper and stainless steel are less common because they are more expensive. It doesn’t rust and can be easily shaped.

- Stainless Steel: Like copper, stainless steel doesn’t rust or corrode, making it expensive to install as well.

The type of material you choose for your commercial building will depend on your budget and the location of your business. While the different materials do have basic similarities, they do have some important differences. When you’re considering a metal roofing system for your business, be sure to take the material into account too.

Insulating a Metal Roof

We’ve already discussed how metal roofing systems are energy-efficient, but there’s another factor that gives this type of roof that quality. Even commercial metal roofs need insulation.

Insulating your metal roofing system can occur at installation or afterward. There are a number of different techniques and types of insulation that can be used on a metal roofing system.

When your commercial metal roof is installed, the metal exterior roofing isn’t the only part. First, there is a base layer that supports the metal. The insulation goes in between that bottom layer and the metal. When the insulation is inserted, typically a foam, it needs to be waterproofed. The insulation is sealed in place and protected in case any moisture does leak through the roof. The metal is then installed over the top.

When you’re adding insulation after the roof was installed, you have to go in from the bottom. Insulation doesn’t have to be packed in — there can be some space in between it. The insulation can also be cut to fit into the different spaces that you need it to go. And when you’re inserting the insulation, use caution. Be sure to avoid any nails or screws that could damage the insulation.

Contact David Maines For Your Metal Roofing Project

If you’re considering a commercial metal roofing system for your business, call David Maines. We will provide you with a free estimate on a metal roof for your commercial building. You need a trusted local contractor to help with your commercial metal roof installation or repair. To get started, please contact us today!